But still being a very inept builder I had to learn what would give my skis longevity.

However I am no hot ryder; and the thought of destroying my own skis cuts pretty deep.

So to get unbiased testing I had to look for a well seasoned park rat to punish my skis.

Yeah, I don’t think that is an intentionally inconsistent flex pattern.

I know just the guy to replace these.

Since these skis would be piloted by Leland, I took his wants into consideration while designing them.

The end result was a soft and buttery long length park ski dubbed the ‘Paperclip’.

The specs are stated below.

Shape Profile:

120MM Tip/ 88MM Waist/ 116MM Tail, 184CM Length.

Base Profile:

70MM Tip Height, 9MM Tip Rocker/ 2MM Camber/ 65MM Tail Height, 9MM Tail Rocker.

Materials:

2001 Grade, clear PTEX base.

PTEX white tipspacers and clear PTEX (electrical tape graphics) topsheet.

Entropy room temperature cure epoxy.

22mm VDS rubber placed along the edges.

2.2MM x 1.9MM steel edges.

A few notable things about their construction.

Firstly my choice against using some kind of PTEX or ABS plastic sidewall.

Secondly, I chose to use a clear topsheet and clear base.

I personally find the look pretty damn sexy, but it serves a higher purpose.

And with the skiing I had seen that was definitely to be expected.

Hard On Park, a state of the art testing facility.

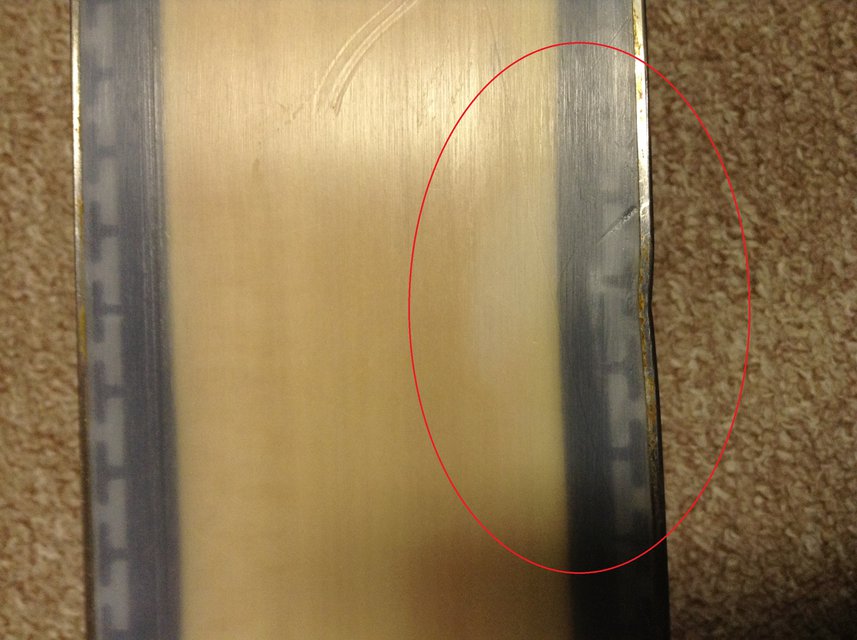

Below is a breakdown of all of the broken down areas on the Paperclips.

Looking through the clear base and topsheet this is easily defined by the bright white blotches inside the ski.

For the most part edge delams initially occur from rail and jib impacts.

But that is only part of the reasoning why edges twist out of skis.

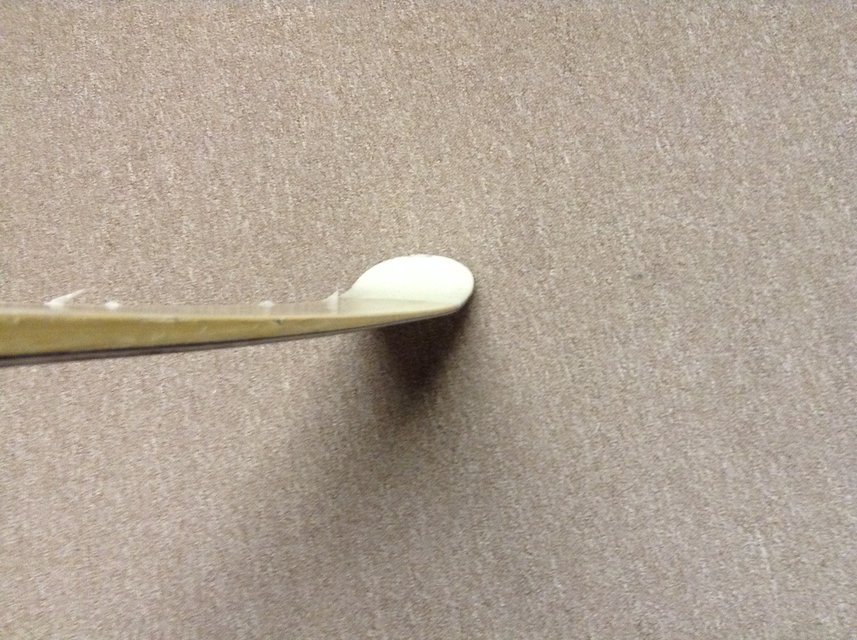

The next little patch is located very close to one ski’s tip.

At least with being a contaminated spot, the areas around the blotch should keep a pretty strong bond.

And being in such a thin area, there is a reasonable chance of that happening.

This is a pretty clear indication that the skis are being rode on the same feet all the time.

This splintering was fairly expected after seemingly endless switchups were carried out on the skis.

Splinters themselves are portions of wood getting sliced, gripped, and cracked away.

The edge delams could be fixed by using a heat cure epoxy that produces a stronger bond between materials.

And damn, colored sidewalls look pretty cool to.

What that havoc might bring to them?

I think we’ll probably see more of the above.

Who know’s maybe I’ll report back with them in multiple pieces; a hard guess to make.

Buttering it outta here!