To put it simply; you cant ski without a pair of skis.

So if skiing really wants to be environmentally friendly, finding a sustainable way to make them is vital.

There arent many teams more stacked with talent thanFaction Skis, they also have a big focus on sustainability.

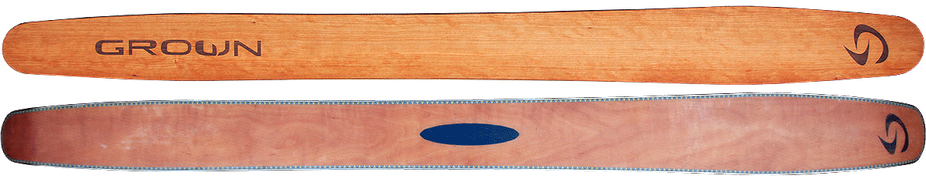

And if you want a pair of homegrown skis, thenGrown Skis,are a company actually doing that!

_

WNDR ALPINE

WNDR Alpine is Matt Sterbenz’s (formerly of4FRNT) new ski brand.

That means, were specifically making materials to provide some sort of performance benefit in outdoor recreational activities.

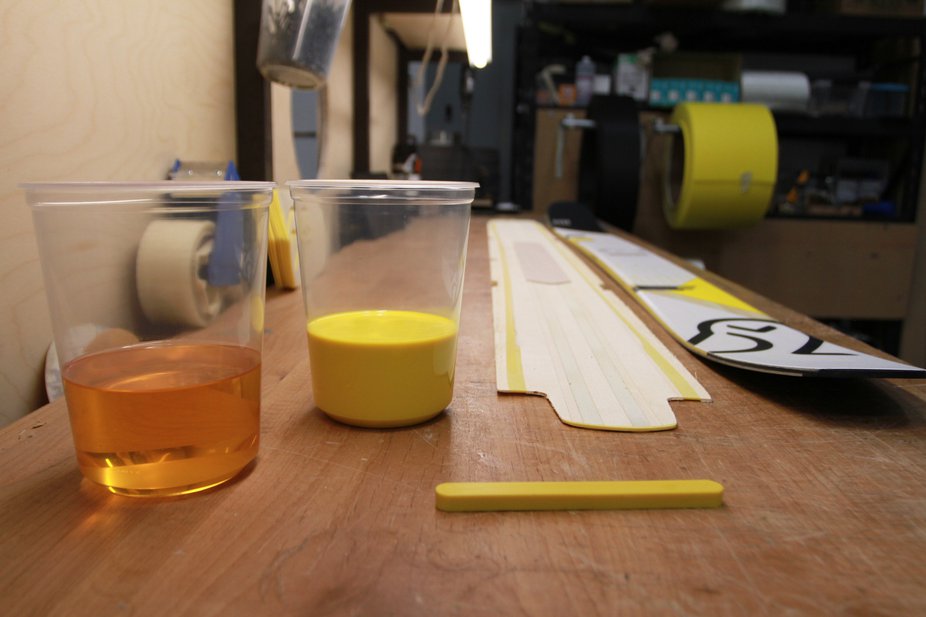

It might not look like much, but this stuff could be vital to the skis of the future.

WNDRhas plans way beyond just using this revolutionary material.

The first is to repurpose our waste material into new material components.

“Right now, we’re grinding all that waste up and storing it.

A second project in the works is to re-purpose base material into other useful products”, he continues.

In the end, that is our goal.

The future of our planets health depends on corporate behavior.

It certainly doesnt have to beSeason,it could be any product that they have.

Just take care of it, wax it, ensure that youre repairing it.

Dont just chuck it when its lost its appeal to you.

The new Season Eqpt.

Over the last decade, Ive gotten my fill and the wanderlust is quenched to a degree.

Ive seen a lot of the world and recently, I’ve just been riding locally.

For me personally, its new, skiing locally.

It dawned on Pollard that every year he would just create a new graphic.

“People were buying them to have the newest product, even if the last graphic was perfectly good.

The longer a product’s life cycle, the more sustainable it is.

Making that as long as possible is the brand’s mission.

LIB TECH

Lib Techis definitely not new to environmentally friendly production.

They are still relatively new on the ski scene though, after years of producing skateboards and surfboards.

Ive been around the block, from a factory standpoint.

My background is mechanical engineering.

When I started atK2,the factory was still in the US.

Ive been atLib-Techfor five years now.

Its quite interesting, in terms of how we do things.

Those colors really do POP!

Doing so has entirely removed the need for solvents in the factory.

And that means you’ve got the option to recycle your waste.

“The polyethylene we use is a high-value material because its super wear-resistant,” Anthony tells me.

We also recycle the excess wood from our core milling process.

But Lib Tech was first”, Anthony concludes.

FACTION SKIS

Sarah Hoefflin tuning a well-used ski.

Credit: Will Derrick

Faction Skishave one of the most talented teams in skiing.

Kelly Sildaru, Alex Hall, Sarah Hoefflin, and even Candide Thovex!

Sustainability is one of their top concerns when developing new products.

They even have an in-house sustainability manager, Sara Asmoarp.

Going forward, their number one policy is to make their products more durable so that they last longer.

“The longer a ski lasts the more sustainable it is”, Sara explains.

Despite the global spread of employees, they minimize travel and have done for years.

The location comes with a number of advantages too.

In 2018, Grown produced the first ski with a 100% industrial hemp fiber/paulownia wood core.

High praise indeed from a man at the forefront of the snowsports industry’s fight against climate change.